Description

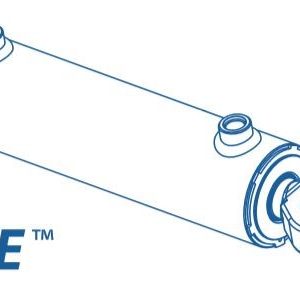

Our in-line hydraulic filters for high pressure applications are made of anodized aluminum and stainless steel material with a max flow rate 100l/m and a pressure up to 350bar

Our in-line hydraulic filters of the 350 Series for high pressure applications are designed for best filtering and max protection to the most delicate system parts. They are connected to the delivery and/or discharge line of the hydraulic system, to retain every impurities of the fluid even the finest particles thanks to a filtering degree from 80/100µm to 10µm.

In-line high pressure hydraulic filters – 350 Series: main features

The in-line high pressure hydraulic filters of the 350 Series are mostly applied on vehicles and machines in the agricultural and forestry, construction, automotive, industrial, marine, wind and transport environments.

- In line operation

- Compact and lightweight

- Maximum strength and efficiency

- High filtering performance and resistance

- With anti-extrusion to overcome even the highest pressure peaks

- Interchangeable filter parts

- Replaceable or washable filter cartridge in sintered bronze

- Reversible filter to ensure filtering in both directions of the flow

- Ease of installation

High pressure in-line hydraulic filters – 350 Series: Technical features

| Max working pressure (bar): | 350 |

| Max oil flow nominal (l/min): | 100 |

| Filtration (µm): | 10-25-40-60-80/100 |

| Filter body: | Anodized aluminum / INOX AISI 316L |

| Filtering element: | Sintered bronze |

| Seal: | NBR / VITON |

| Ports: | BSP / NPTF |

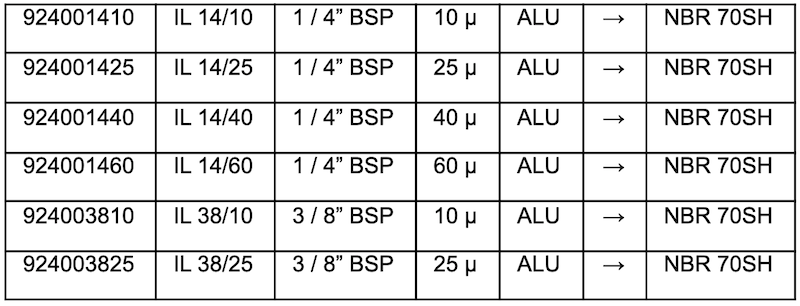

| Threads: | M18/10 – M18/25 – 9/16UNF – 1/2 “ – 1/4 “ – 3/8” |

| Weight (kg): | 0,24 (alluminio) / 0,60 (inox) |

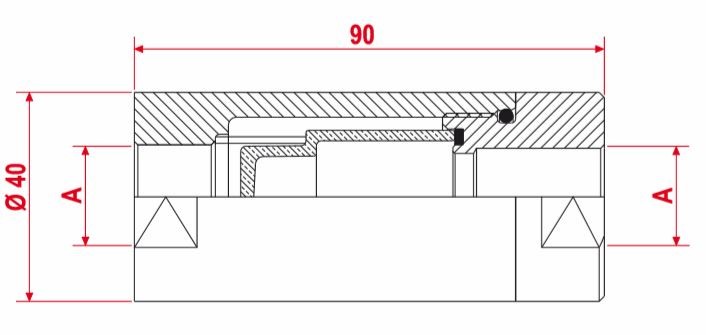

Size

Series comparison

See the full table of series comparisons.

Filter accessories

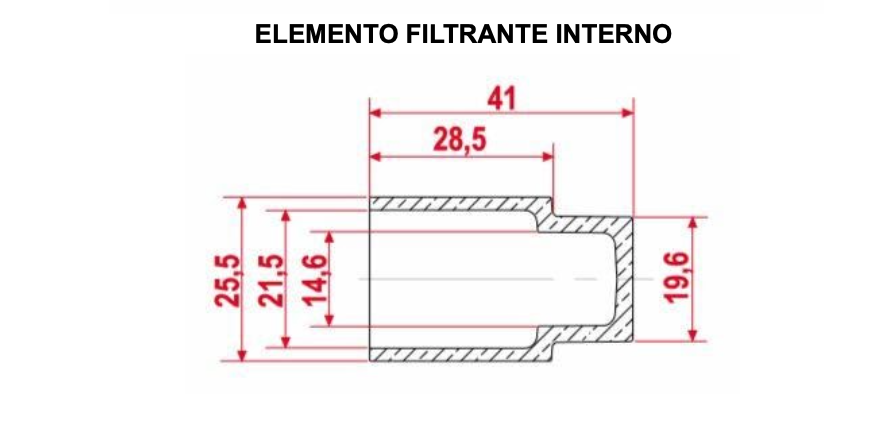

Filtering element

Filter marking:

The 350 Series in-line filters, like all BELL filters, are marked with type, brand, connection, production date and operator.

Customized marking on demand

All BELL products are designed and manufactured within BELL SRL in via F. De Pisis, 5 – 42124 Reggio Emilia (RE) – Italy, according to the Quality Standards that distinguish the MADE IN ITALY from the Rest of the World.