UP series air-hydraulic pumps

UP series air-hydraulic pumps

They are real power units, the UP Series air-hydraulic pumps have replaced the electro-hydraulic power units in many fields of application

BELL SRL designs and manufactures single and double stage air-hydraulic pumps of the UP Series, for single and double-acting actuators with multiple types of drive for multiple fields of application. Real power units, these single and double acting air-hydraulic pumps of the UP Series have replaced electric power packs in many fields of application thanks to their efficiency and performance in any conditions. They are synonymous of high performance and efficiency thanks to high working pressures (up to 1,000bar), large oil flow rates (l / min) and oil tank capacities suitable for every use (from 2.4L up to 20L)

UP Series single and double acting air-hydraulic pumps: main features

Designed to work even at operating pressures of 1,000 bar in a continuous cycle. Designed to use hydraulic fluids and glycols, for the operation of single and / or double acting cylinders depending on the configuration.

Connectable to the normal pneumatic network 2.8 / 8.3 (max 10 bar)

Replaceable internal air filter, as well as an externally adjustable relief valve for the protection of the circuit components.

- UPC version (Ultra Air Pump CETOP configuration) it is possible to operate the unit remotely through valves with electric, hydraulic or pneumatic control (optional).

- UPF version (Ultra Air Pump PEDAL configuration) the release valve for discharging the pressurized oil is built into the unit and is operated by the pedal. This valve is hydraulically balanced to eliminate valve opening shocks and allows a fast and controlled return of the flow. The oil pressure obtained is not affected by a possible pressure drop in the air duct, even if the pneumatic network is disconnected

- UPR (Ultra Air Pump REMOTE configuration) and UPRD (REMOTE DOUBLE) version for drives with remote control for single and double acting cylinders

- UPM version (Ultra Air Pump MANUAL configuration) equipped with a lever distributor valve to control the flow of oil from one branch to the other of the double-acting cylinder

- UPHC version (Ultra Air Pump HYDRAULIC CYLINDERS configuration) to drive up to five single-acting actuators simultaneously

- UPD version (Ultra Air Pump DOUBLE MOTOR) with double pneumatic motor for large oil capacities and high flow rates at any pressure.

- UMP (Ultra MINING Pump) version for efficient use in any harsh conditions, dual functionality (pedal and flow distributor hand valve), integrated pressure gauge, air dryer and lubricator included.

UP Series single and double acting air-hydraulic pumps: additional benefits

- Inlet air filter and internal oil filter to protect the pump and the system parts

- Oil tank outlet for the return to discharge of in-line valves (optional)

- Oil level indicator in Pyrex to ease the oil level check and refill

- Externally adjustable relief valve

- Versatile install in both horizontal and vertical position

- Low energy costs

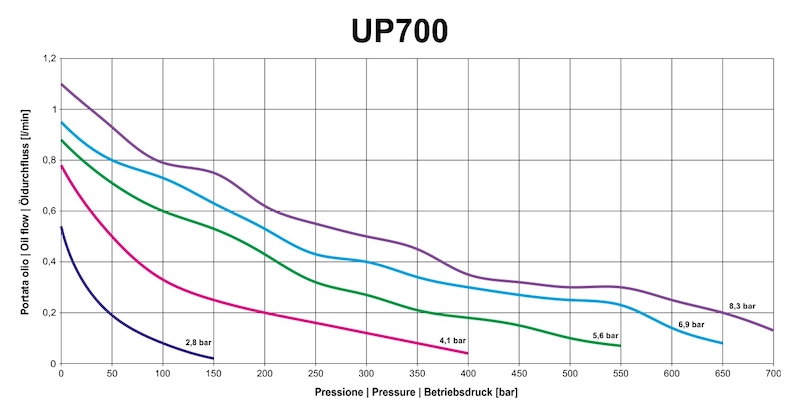

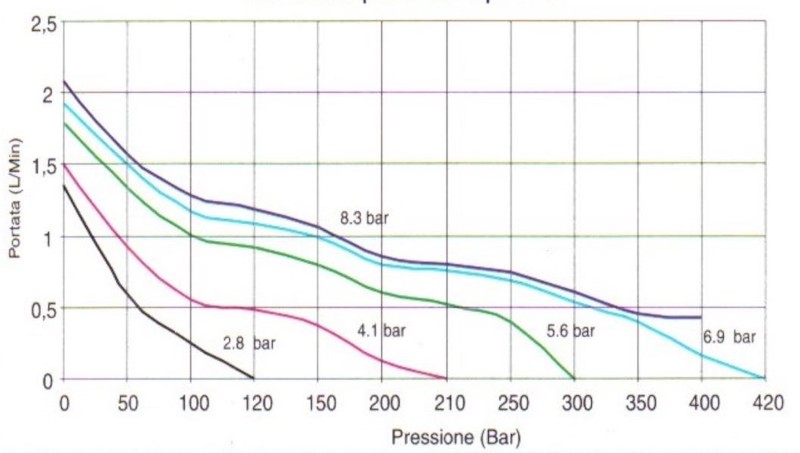

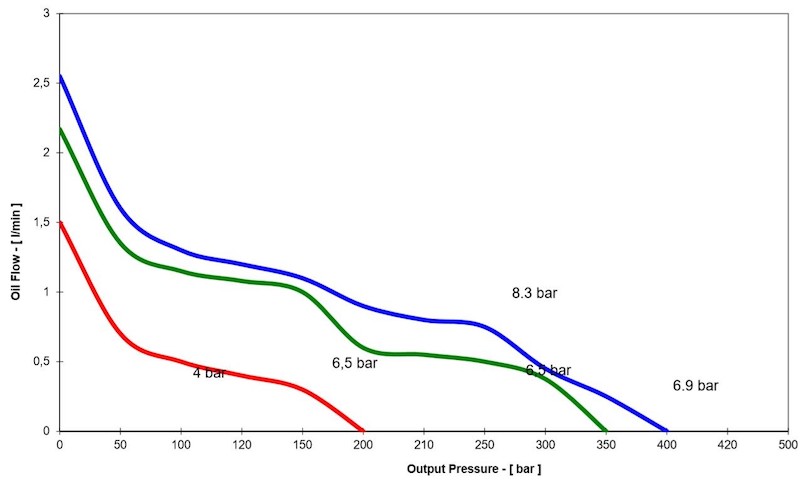

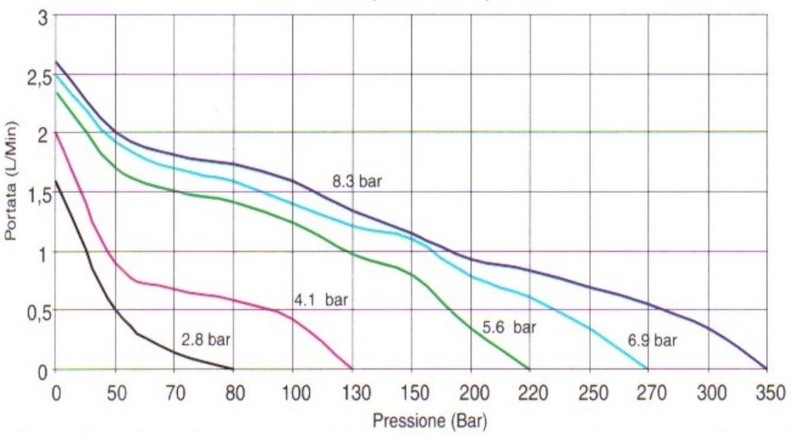

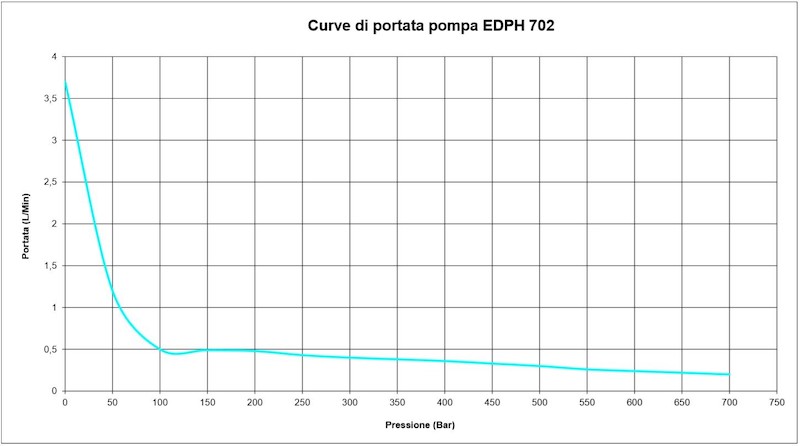

Oil Flow (l/min)

The hydraulic pressure of the pump depends mainly on the reduction ratio, the calibration pressure of the relief valve and the pressure of the pneumatic inlet air.

The hydraulic pressure increases or decreases proportionally to the increase or decrease of the inlet air pressure.

Therefore the flow rate (l / min) increases or decreases proportionally to the increase or decrease of the hydraulic pressure

The flow diagrams show the performance trend in combination with the working pressure at several inlet air pressures (ref. to the technical data sheets)

Oil flow (l/min) diagrams

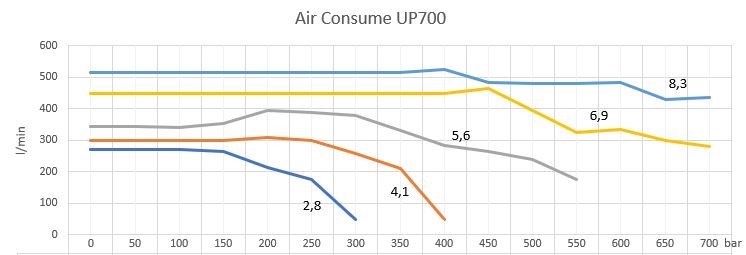

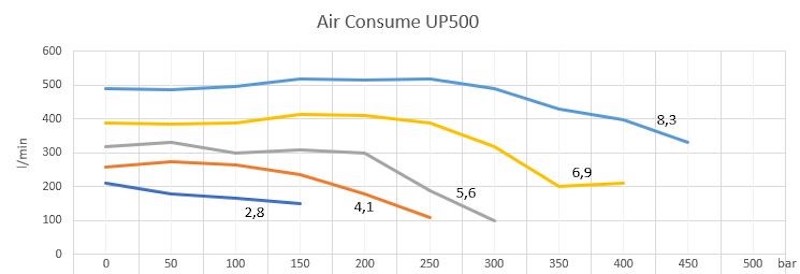

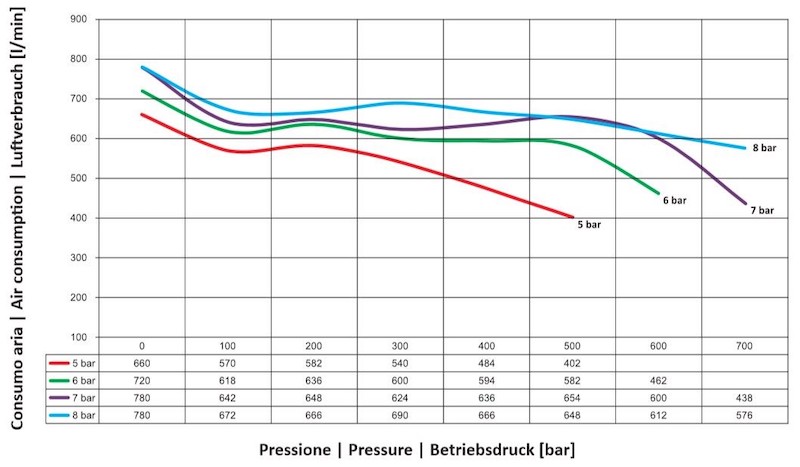

Air flow (l/min)

BELL pumps of the HP Series work in an air inlet pressure range from 2.8bar to max 10bar

The average air consumption is 340 l/min.

An air lubricator is not required, however it is highly recommended to have a condensate filter to dry the inlet air.

The diagrams show the air consumption related to the working pressures and the flow rates (ref. to the technical data sheets)

Air consumption (l/min) diagrams:

Stall/restart pressure

All BELL pumps of the UP series can work at a constant hydraulic pressure by adjusting the air inlet pressure (stall).

The air inlet pressure has to be set-up so that the pump stalls at the required output pressure value (the calibration of the relief valve must exceed the operating pressure value so as not to compensate).

Whenever the hydraulic pressure decreases (circuit leaks – pressure drop), the pump compensates automatically and restores the set value (the air pneumatic network must be always connected to the pump).

The stall/restart diagrams show the pressure values in different conditions.

It is recommended to check the settings by restarting the pump from time to time

A slight loss of air during operation in these conditions is completely normal.

All BELL products are designed and manufactured within BELL SRL in via F. De Pisis, 5 – 42124 Reggio Emilia (RE) – Italy, according to the Quality Standards that distinguish the MADE IN ITALY from the Rest of the World.