Description

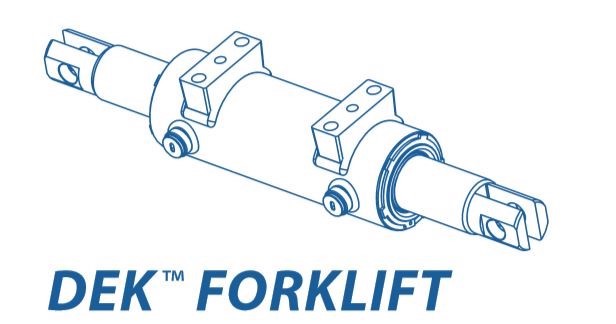

Flanged fork steering cylinder with crossing stem

Among the hydraulic actuators of our production there is the DEK-FORKLIFE Series, a range of fork steering cylinders for agricultural vehicles, earth moving vehicles and forklifts.

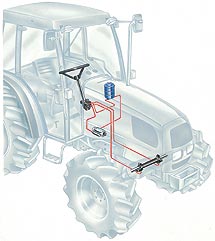

The hydraulic actuators automate the entire driving process, by minimizing the human interaction with the machine. The hydraulic cylinders supply controlled energy to the driving system, so that the driver can turn the steering wheels through a minimal effort in medium speed conditions. This effort is considerably reduced even when the vehicle is moving slowly or is stationary. The hydraulic power of the actuator ease the mechanical operation of the machine, giving an optimal output in terms of linear, oscillatory or rotary movement.

DEK-FORKLIFT series hydraulic actuators: features

The DEK-FORKLIFT Series of hydraulic fork steering cylinders are designed for the agricultural and construction vehicles: tractors, earthmoving vehicles, backhoe loaders, dump trucks, wheel loaders, graders, municipal vehicles, forklifts.

Here are the main features:

Hardened stem

Hardened stem- Rod guide systems in treated metal or with applied rings

- Stainless steel rod

- ASTM B117 96h corrosion resistant chrome surface

- Hardened or chromed stems

- K-BOND piston group

- Monolithic stems or friction welding

- Auto-Venting System

- Application: steering axles or articulated vehicles

- Designed to position sensors

Fork steering hydraulic cylinder: technical specifications

- Max working pressure (bar): 120

- Compatibility: Double acting

- Working oil temperature (°C): min – 30 – Max std + 100 – Max avail + 120

- Stem diameter (mm): min 22 – Max 55

- Piston diameter (mm): min 40 – Max 75

- Stroke (mm): max 300

- Weight (kg): from 2 to 7

Size

Series comparison

Consult and download the comparison table

Spare parts for steering fork cylinders

- Seal kit

- Cylinder heads

All BELL products are designed and manufactured within BELL SRL in via F. De Pisis, 5 – 42124 Reggio Emilia (RE) – Italy, according to the Quality Standards that distinguish the MADE IN ITALY from the Rest of the World.