Air-Hydraulic Pumps

Air-Hydraulic Pumps

Air-Hydraulic Pumps

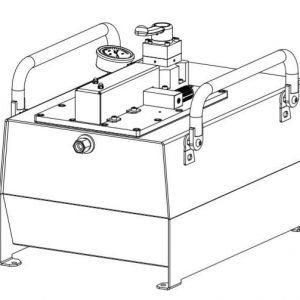

Small and handy air-hydraulic pumps

We manufacture air-hydraulic pumps with a compact design, they are portable and ensure excellent handling. The main feature of these industrial equipments is to exploit the compressed air of the normal pneumatic network (2.8 up to 10bar) through a pneumatically operated linear motor which generates a high hydraulic output pressure (up to 1000bar).

The fields of application are multiple and may vary like any hydraulic application in different sectors can be equipped with our pumps.

Air-hydraulic pumps: main features

- Multiple configurations with oil tanks of different oil capacities – from 1.4L up to 20L

- Oil output pressures (bar) inversely proportional to the flow rate (l/min) and the inlet air pressure (bar). They vary depending on the size of the piston size: from 0.85 to over 8.5 l/min flow rate with air inlets from 2.8 up to 10bar (max) and working pressures up to 1000bar.

- Replaceable internal air filter

- Externally adjustable safety valve to protect any hydraulic parts against possible overloads, regardless of the inlet air pressure setup.

Industrial air-hydraulic pumps: advantages

- Operational principle:

- Take advantage of the compressed air of the normal pneumatic network (2.8 up to 10bar) through a pneumatically operated linear motor that generates a high hydraulic pressure (over 1000bar).

- Multiple possible configurations with oil tanks of different capacities – from 1.4 up to 20L depending on the versions and models.

- Oil pressures (bar) inversely proportional to the flow rate (l / min) and the inlet air pressure (bar). They vary according to the size of the internal diameter of the pump: from 0.85 to over 6 l / min of flow with air inlets from 2.8 up to 10bar (max) for operating pressures over 1000bar.

- Connection to the normal pneumatic network, which almost every company / workshop is equipped with, or to any source of compressed air.

- The pneumatic motor of the pump receives compressed air and generates the hydraulic force necessary to do the job.

- The hydraulic circuit remains pressurized via a check valve and does not drain until the release valve is opened.

- In the event of normal pressure drops, with the pneumatic network connected to the pump, the hydraulic pressure is restored automatically.

- In the event of normal pressure drops, with the pneumatic network connected to the pump, the hydraulic pressure is restored automatically.

- Replaceable internal air filter

- Externally adjustable safety valve to protect the hydraulic components against overloads, regardless of the inlet air pressure.

- Oil Flow (l/min)

- The flow rate (l / min) increases or decreases in proportion to the increase or decrease in the hydraulic pressure.

- The hydraulic pressure of the pump depends mainly on the reduction ratio, the calibration pressure of the relief valve and the pneumatic inlet air pressure.

- The flow diagrams show the performance trend as a function of the operating pressure at the various inlet pneumatic pressures (ref. technical data sheets)

- AIR-FLOW (l/min)

- Average air flow required 340 l / min.

- Minimum inlet air pressure of 2.8 bar up to a maximum recommended pressure of 10bar.

- An air lubricator is not required however, it is recommended to have a condensate filter.

- The diagrams show the relative air consumption based on pressures and flow rates (ref. technical data sheets)

- Stall / Restart

- All BELL pumps can also operate at constant hydraulic pressure by adjusting the pneumatic inlet pressure (stall)

- To obtain this effect, it is necessary to adjust the pneumatic pressure so that the pump stops (stall) at the desired pressure value (the setting of the relief valve must exceed the operating pressure value so as not to start working).

- Whenever the hydraulic pressure decreases (circuit leaks), the pump restarts automatically and restores the set value (provided that the pneumatic network is always connected to the pump)

- The stall / restart diagrams show the pressure values at the relative conditions (ref. data sheets).

- It is recommended to check the settings by periodically restarting the pump

- A slight loss of air during operation in these conditions is completely normal

- Transportability:

- Extremely portable, compact and lightweight and can be used wherever a source of compressed air is available.

- Extremely low weight, depending on the model chosen and the various configurations, from about 5 kg (HP model) up to about 35 kg (UP model with 20L tank).

- This is a significant advantage if you have to carry out field work, such as maintenance and assembly / disassembly.

- For this type of work, very short operations are enough to obtain high hydraulic pressures (eg 700 bar correspond to a force of approximately 25ton).

- Having such hydraulic power through an extremely portable and compact product allows for fast and effective intervention.

- Noise:

- All BELL pumps are silenced with reduced noise to protect the operator and the surrounding environment.

- The silencer present on all pumps maintains a noise level in line with the most rigorous quality standards.

- Main fields of application:

- Operation of single and / or double acting cylinders according to the models in the range.

- Use in any hydraulic application, especially in those where there is a need for high pressures and moderate and controllable oil flows, in order to always ensure a certain precision in operations.

- Applications:

- From the industrial sector for fixtures, extractors and presses, punchers, crimpers, to the automation sector, clamping, pressure machining, to the automotive sector, lifters, hydraulic ratchets, pulling arms, crosspieces, bead breakers, etc.

- Environments where there is a potential risk of fire or explosion, as the compressed air is in itself compatible with any type of situation.

- Lifting of heavy objects (eg truck / car / motorcycle lifts)

- Automation (clamping of pieces under pressure during automatic precision machining)

- Pressing (eg bearings)

- Extraction (eg bearings)

- Bead breakers (eg tires)

- Tensioning

- Moulding

- Punching

- Cutting of blocked nuts, cables

- Straightening of steel structures (pull benches) and car bodies

All BELL products are designed and manufactured within BELL SRL in via F. De Pisis, 5 – 42124 Reggio Emilia (RE) – Italy, according to the Quality Standards that distinguish the MADE IN ITALY from the Rest of the World.