HYDRAULIC FILTERS

HYDRAULIC FILTERS

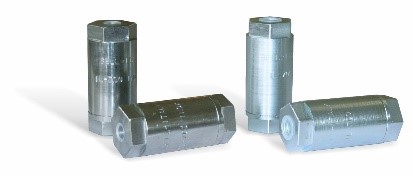

Filters for high pressure hydraulic systems

Hydraulic filters useful and suitable for a high protection of the most delicate parts of any hydraulic system

Filters for high pressure hydraulic systems, up to 700 bar for the best protection of every parts. Installed in combination with the traditional filtering systems, our high pressure hydraulic filters are directly connected to the delivery or discharge line of the hydraulic system to capture any impurities present in the fluid, even the finest particles thanks to a filtering degree from 80/100 µm to 10 µm. They are sturdy and durable with high-quality materials and treatments which last for the entire filter life.

Three filter Series which differ from each others for material, performance and design :

- 350 SERIES: hydraulic filters, high pressure, in line and 90°layout, in anodized aluminum and stainless steel material, max oil flow 100 l/min, output pressure up to 350bar

- 500 SERIES: hydraulic filters, very high pressure, in line and 90°layout, in anodized aluminum material, oil flow max 100 l/min, output pressure up to 500bar

- 700 SERIES: hydraulic filters, very high pressure, in line, in galvanized steel and stainless steel material, oil flow max 100 l/min, output pressure up to 700bar

Benefits:

- Compact and extremely limited overall size

- Lightweight (250g)

- Max strength and efficiency

- High filtering performance and resistance

- Interchangeable filter parts

- Filter cartridge, replaceable or washable, in sintered bronze with conical shape to withstand even very high pressures without collapsing (up to 700bar)

- Reversible filter to ensure filtration in both the directions of the flow

- Easy install

- Inspection cap of the filter cartridge for quick inspection and cleaning (90 ° filter)

Technical features:

- High working pressures up to 700bar

- Large oil flows (nominal oil flow up to 100 l/min)

- Standard filtering degrees: 10, 25, 40, 60 e 80/100 µm

- Filter body and cap treatened to best resist to any external agent:

- Alluminum, galvanized steel and stainless steel

- Standard and Viton seals available for mineral oils, emulsions and very aggressive sintetic fluids

- Oil port threads in universal BPS and NPTF sizes for the best versatility on applications

Main fields of application:

- Agricultural and Forestry: machinery, tractors, irrigation systems, …

- Earthmoving : cranes, excavators, elevators, …

- Automotive : workshops, car-lifts, forklifts, hydraulic jacks, diesel pumps,….

- Industry: large hydraulic systems, generators, intensifiers, multipliers,….

- Marine: turbines, large hydraulic systems, offshore,….

- Wind: turbines

- Transport

All BELL products are designed and manufactured within BELL SRL in via F. De Pisis, 5 – 42124 Reggio Emilia (RE) – Italy, according to the Quality Standards that distinguish the MADE IN ITALY from the Rest of the World.